The Dictionary of Sydney was archived in 2021.

Sydney Flour Mills before 1850

Citation

Persistent URL for this entry

To cite this entry in text

To cite this entry in a Wikipedia footnote citation

To cite this entry as a Wikipedia External link

Wheat was a staple European food and the British brought it to Australia in 1788 expecting it be the basis of their diet. Estimates of the amount consumed by an adult male in the nineteenth century vary but 8 bushels a year is widely used. So, to be well fed, the colony needed 7-8,000 bushels a year, more than they had for some time. Before it could be consumed, however, the grain needed to be ground into flour, so flour milling became an immediate and necessary secondary industry in the colony. And as stone-ground flour has little keeping capacity, mills needed to be close to the consumers.

Sources of wheat in the early colony were limited, a difficulty aggravated by distance, poor harvests in Europe and problems in the USA. Phillip brought four millstones and grain from the Cape, but there was no one to set up a mill [1]. In October 1788 he sent the Sirius on a perilous journey to the Cape for more grain, and she returned on 8 May 1789 with five months' supply. In 1790 the 200 bushels of wheat that were harvested were kept for seed [2]. In April 1794 Lieutenant David Collins was lauding the sowing of 400 acres in wheat on the public account describing it as 'that essential grain.' By 1799, 6,000 acres were under wheat, which should have been sufficient, but the real yield was variable. In fact 'Indian corn' seems to have been a more substantial element of the early convict diet.

The first mills

Even though their market was restricted, local mills were essential and the trade of a mill builder or miller was highly skilled requiring familiarity with gearing and ratios as well as an understanding of wind and water velocity. As the first steam flour mill only opened in England in 1784, the power sources initially considered in the colony were wind, water, animal or human. As Sydney's location did not offer convenient and close sites for water mills, and both animal and human power were limited in the first decade, Phillip soon appealed to Secretary Nepean to send out some windmills, and with them a competent millwright, as that class of tradesman was not to be found among 'the bond'. Meanwhile the problem was passed on to the convicts who were issued with grain, not flour, while the military were also left to grind their own.

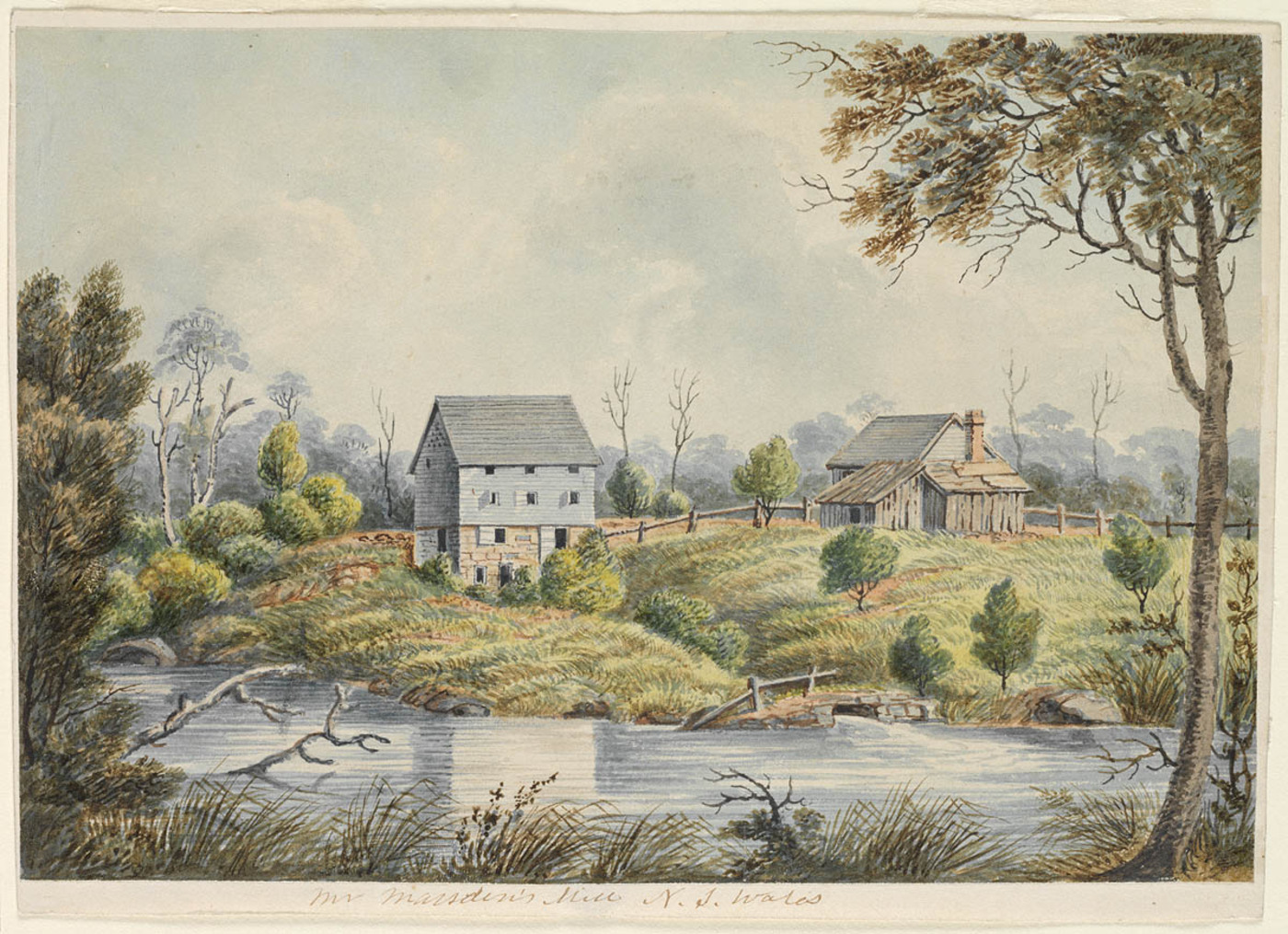

Phillip could offer little incentive for competent millwrights or millers to migrate. The two sent, Thomas Allen and James Thorp, proved incompetent and nearly a decade of settlement passed before the first windmills were built in Sydney, although Collins's reference to 'wheat, passing through the large mill at Parramatta' in November 1793 suggests that Allen had finished the water mill there at Mays Hill, which would make it the first in the colony. Unfortunately the brittle timber used to construct the Parramatta mill caused it be '…unequal to the consumption of the settlements. The cogs frequently broke and hence it was not of any very great utility' [3] .A further problem was the unsuitability of the local stone for grinding. In 1792 millers returned to using iron hand mills made by a convict blacksmith.

In 1793, Lieutenant-Governor Grose claimed to have found a carpenter, James Wilkinson, who could build a mill able to grind enough for the limited numbers in Sydney [4]. According to Collins he did this with the help of his fellow prisoners alone, but there were problems because the local timber used had not been properly seasoned. Nevertheless, it worked for a time and Wilkinson proposed improvements that would assure its proper functioning.[5].

John Baughan (or Bingham), formerly a convict whom David Collins described as 'an ingenious man', had undertaken to construct a different type of mill to Wilkinson. Both mills were to be erected on the open spot of ground formerly used as a parade by the marine battalion'. Baughan's mill commenced operations on the 10 March 1794 with nine men working a capstan bar. It was reported that it ran so smoothly that a bushel (approximately 60 pounds of wheat) was ground in seventeen minutes. James Wilkinson's nearby mill commenced operations a month later but it was soon abandoned and Baughan was commissioned to replace it by another of his own design, which he did by July 1794. Collins was glad to see coarse ground flour but it would be some time before mills were sophisticated enough to provide fine flour, let alone use Oliver Evans' new improved milling system [6].

Early mills

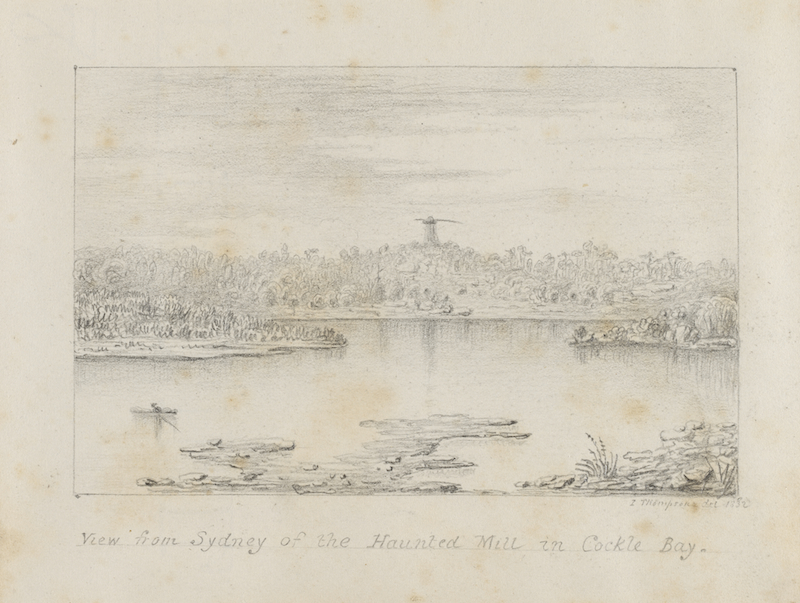

In a struggling penal colony with a great shortage of capital and mostly unskilled and unwilling convict labour, the government was responsible for the provision of necessary services. Mills were expensive to build and needed constant maintenance, a fact that the military governors did not well understand. In September 1795, parts of a large windmill arrived with Governor Hunter on the Reliance. In June 1796, building began for the first of two windmills that marked on Charles Grimes' 1800 map of Sydney on the high ground on the east of Cockle Bay. Hunter wrote to the Duke of Portland that he was

erecting upon the high ground over Sydney a strong, substantial, and well-built windmill, with a stone tower, which will last 200 years, and we are preparing materials for such another at Parramatta [7].

The mill, which drove a single stone, was finished in February 1797. However, the design of the stone tower was not adequate for the strains of the shifting weight of the sails and restricted its operational capacity.

The next mill the government embarked on in 1799 was also a stone tower (a modest 36 foot or 11 metres high) on the same ridge over Cockle Bay and an improvement on the first. This mill was eventually assigned to the military, from 1800 to about 1832. Nathaniel Lucas, an ex-convict and carpenter who had learned the skills of a millwright, built one more windmill for the government in 1806.

Lucas's own mill, built around 1805 next to the government bakery where the Sydney Conservatorium of Music now stands in the Botanic Gardens, passed to Henry Kable. John Palmer, the first government commissary also had a mill to the south of Lucas's and operated it together with the government bakery. [media]In Joseph Lycett's view of Sydney in 1822 this second mill stands as a tower in front of the barracks while the other two in the area, Boston's and Lucas's, have gone.

The Sydney Gazette claimed that Lucas's mill was the first post mill built [8]. A post mill sat on a heavy timber post held up by a brace on the ground. In its simplest form, the miller or an animal turned the post pushing a long pivot. The angle of the sails was adjusted to the prevailing winds and simple gearing carried the power down to the stones. The sails were usually cloth 'common sails' adjusted like sails of a ship. This simpler form of windmill was easier to manage [9].

As the government only ground wheat for the stores, free settlers and convicts with grain had to manage its grinding for themselves and milling became an attractive enterprise. Only free settlers closely connected to the government were permitted to build the first private mills. In 1800, John Boston, a surgeon and apothecary, began building his mill in the Domain. Boston, who came to the colony as a free settler around 1795, had already attempted, unsuccessfully, to manufacture salt and set up brewing. Boston's mill was a cylindrical tower with a sack hoist and it soon broke down or was demolished. Grimes' 1800 map also shows a mill on this site.

[media]As the colony's population increased and the shortage of grain diminished, more people with suitable skills became available and more mills were built by those with capital who saw mills as a useful investment. A windmill run by Garnham Blacxell was built on the Macarthur land on Pyrmont in 1809 and a further three post mills were built on what is still called Millers Point in the Rocks, probably round about 1813. The physical life expectancy before substantial repairs of such a mill was usually about 25 years. By 1826 the Pyrmont mill was already in ruins and by 1839 two of the Millers Point mills had disappeared.

By the 1830s nearly all Sydney's windmills were described as having 'common sails'; that is to say, their sails were canvas, not the patent sails that had been available for nearly half a century. A post mill, however, had the added advantage of not being built into the ground, and therefore it was relatively easily moved from site to site. The disadvantage was that it was not well suited to the finer aspects of flour preparation that required bolting and sifting machinery [10].

[media]Watermills were easier to build and run and by 1810 at least one watermill had been built at Parramatta and people were considering the possibilities of the streams that ran into Rushcutters Bay. Ex-convict Thomas West built a mill at Barcom Glen on the creek that was still known in 1843 as West's creek. Said to be the first water mill in Sydney, it was opened by Governor Macquarie on 14 January 1812. The Sydney Gazette described the water mill as direct drive, which implies a horizontal mill with no external waterwheel of any kind. However West's son described the water being impounded by a weir and dam at the bottom of Liverpool Street and the mill 'with its overshot water-wheel; stood about forty yards further down the creek'. West's mill worked for some years although it was closed before 1832 [11] as the water supply was inadequate and dairying and cattle-raising became more profitable [12].

The year 1813 saw the first steam engine brought to the colony, set up on Cockle Bay, and fitted up to grind grain. This was something of a gamble as steam engines needed constant care and adjustment, and spare parts were in short supply. A steam mill of sufficient horsepower could run all the auxiliary machinery that enabled a finer quality of flour to be produced and the residue sold as seconds, but the capital cost of building such a mill were considerable - several thousand pounds even then - and the costs and skills of running a steam engine, with its demand for wood and coal were far greater than those of running a wind or water mill.

A difficult enterprise

Milling charges were only a moderate percentage of the total price of flour so the miller's room for manoeuvring profit was limited. Part of the problem with flour milling as a business was the fluctuation in supply and demand. If the supply of grain was short the price might rise dramatically but if there was an oversupply people did not want to consume more and so the price would fall. As steam mills were competitive only where they could process large volumes, people continued both to build windmills (and occasionally a water mill) and to compete successfully with the steam mill [13].

Business was also effected by the type of grain on offer and when it was harvested. In 1823 and in other years the harvest was scanty and famine threatened, so the millers had difficulty in obtaining local grain [14]. Even in 1837, a considerable amount of grain was still being imported [15]. Mills could not rely on an adequate supply of local grain, and with NSW supplies frequently in deficit in the first half of the century, millers regularly imported grain to meet the city's needs exposing their businesses to the mercy of changing import prices and volumes. To mill well, grain needed to be of uniform size and consistency. A general lack of capital and initiative to 1850 meant that local grain was often poor quality [16].

Constant change of wheat varieties also required adjustments of stone height and speed. Different qualities of wheat needed different treatment — hard wheat and soft wheat cannot be milled in the same way, winter and spring wheat differ and so on. It would appear from Wentworth's early account in 1819 that the common varieties in the colony were red and white Lammas and the Cape or bearded wheat. In 1850s the English variety Red Straw was introduced, and a selection from it developed in South Australia and known as Purple Straw became the most popular variety in 1860 because it was an earlier maturing variety and so escaped rust [17]. In 1819, the harvest started in November and was over by Christmas [18]. Grain was then brought in and stored in granaries until the flour was needed.

Grain needed to be dry and free from debris before it was milled. While the steam mills could automate the proper preparation of the grain to produce fine flour, seconds and by-products, they needed to be working constantly if a profit was to be made and that required experience and skill (and the hope that major parts would not break).

John Dickson, who brought out the first steam engine, was a highly trained engineer with British experience and patents. He arrived with equipment estimated to be worth £10,000, obtained a sizeable grant and evidently kept his engine going. The steady increase in population meant that there was a similar steady increase in demand for flour. Dickson's was not a powerful engine – 14 and 16 horsepower are mentioned (the first steam mill in England had two 50 horsepower Boulton and Watt engines) and, even so, he may have contemplated running sawmills, breweries or tanneries alongside it to use the power when grain was in short supply.

Dickson had the only steam mill in Sydney for nearly a decade and the growing population in the early 1820s meant that milling was profitable. The experienced and established milling families were able to take advantage of a seller's market. Other entrepreneurs also built water and windmills and, in Charles Gordon's case, possibly a horse mill in the same period. Governor Macquarie encouraged the building of watermills. Samuel Terry obtained a grant in 1819 on the understanding that he would build a 12 horsepower mill on the edge of Botany swamp in what is now Kensington (for a time called Lachlan Mills estate) and another, the Lachlan mill, on a stream that ran from South Head to Botany [19]. These mills were far from the centre of Sydney town but water transport, by now available, made them viable.

In 1822 John Lucas, Nathaniel Lucas's son, built his first watermill even further out at Harris Creek and a second mill at Woronora in 1825. This gave him the name of John the Miller. After the first water mill was ready, John Lucas asked Governor Brisbane to permit him to call the mill Brisbane Mill, as it was the first mill to be erected after Brisbane's arrival in the colony. In 1824 the Brisbane Mill was selling a bushel at "as low a price as in Sydney" [20].The mill at Woronora had a permanent supply of water because it was on the upper reaches of what is now the Woronora River at the head of the tidal waters adjacent to the old ford. John stated that there was sufficient water to grind one thousand bushels weekly.

By 1819 there were 54 bakers in Sydney town. New watermill sites were scarce and so windmills continued to be much in demand although there was often a shortage of millers with the particular skills needed to work them. Further windmills were erected in the 1820 and 1830s, mainly on the ridge along South Head Road. The first were the post mills removed from the Domain area but by 1826 two striking stone tower mills were built. There are pictures of these mills from the period which suggest that they were fitted with more sophisticated devices for raising the sacks and turning the caps. Such a mill was worth between £1400 and £2,000. The Gazette puffed the mill built by Ashley and Thomas Hyndes, adjacent to Craigend, as a spacious and very handsome windmill. It had two pair of stones and a smutter and was clearly a very tall tower (five storeys rather than the usual three) if the height of the sails at their highest point above the ground (32 metres) is accurate. Dickson's apprentice, Thomas Barker, built another very large tower mill fairly close by, and these are the two mills most frequently sketched.

Barker was a skilled miller but others who had mills built at this time were successful businessmen with no particular links to flour milling, like the ex-convicts Robert Cooper, Daniel Cooper and Solomon Levey. The roles of mill builder, mill owner and mill operator were now generally distinct, and as the mills might go by the names of either owner or miller, there is some confusion over who built and managed some of these mills. Mills were bought and sold and millers came and went, so an individual might be involved with more than one.

For example, Thomas Clarkson put up a post mill in 1819 and by 1822 this was the first mill to be associated with the French ex-convict Francois Girard who was at this point primarily a baker (and also a dancing master). After his pardon in 1825 Girard rapidly pushed into the business, applying for land on which to build a mill and a spermaceti factory, refusing all sites except the one on Woolloomooloo Hill. When the mill was built (by Ashley and Hyndes), he offered the lowest tender to secure the contract to supply the military and convict establishment with bread for twelve months. He was permitted to mix wheat and Indian corn in the bread he baked but probably adulterated it further. Certainly his loaves provoked a near riot among the military who went to his house and threw them back at him through the windows, so incensed were they [21].

In the early 1830s demand for flour was great enough for Robert Cooper to start a horsemill in Pitt Street while he was waiting for his windmill to be permitted. In 1838 Maclehose claimed that there were eight steam mills on Darling Harbour [22]. At least three of the mills on the ridge were still going in the 1850s however, by then steam was inexorably taking over [23]. The increased availability of skilled engineers and architects made this a more reliable undertaking, although windmills were still worthwhile. The last windmill built was that built by Henry Hough, who already had a mill in the city in Waverley. Hough's mill, a post mill on an octagonal base, was first mentioned as working in 1841 and was still going in 1871, the last it seems in Sydney.

Steam mills

Although windmills continued to be profitable until the 1850s, the construction of a steam mill at Parramatta and a second in 1825 on Cockle Bay north of Dickson's 'below the old burial ground' marked a significant moment of change in the industry. The second Cockle Bay mill seems to have been built for Daniel Cooper and Solomon Levey 'of the Waterloo Company', the colony's biggest money lenders who were also involved with windmills on South Head Road and at Parramatta. The water frontage was ideal for the delivering goods and they had access to the natural water reservoir and so built a five-storey grain store.

It did not stay in their hands for long. Girard may have briefly held it, 'paying for the use of it £1,000 yearly' said the Australian but they sold it in 1826 to Thomas Barker for £6,000. This was a sum he evidently did not have as he entered into a mortgage to Cooper and Levey for £5000. The fresh water for the boiler came from two streams flowing under Sussex Street into two millponds clearly marked on later maps. Cooper and Levey's steam engine was only 14 horsepower but from 1828, under Thomas Barker, it was upgraded. In 1833 a new five-storey mill that could operate separately was built and by 1840 the mill had a 14 horsepower engine driving two pairs of stones and a 30 horsepower engine driving four pairs of stones while three dressing and smut machines were in use. These assets were 'sold' to Donald Larnach for £25,000 as the company tried to trade its way out of insolvency.

Girard had to wait until 1832 for his chance to build a steam mill of his own on a site at the other end of Darling Harbour, the junction of Sussex and Napoleon streets. He ordered from Aspinall, Brown and Co, a firm recently established in Sydney, a 14 horsepower engine costing about £700 with a full range of French burr stones, pearl barley stones and the like. This arrived at the end of 1833. The waterside was said to be 100 by 150 foot (metres), the stores 90 by 40 foot (metres) and six storeys high, all of which he claimed cost him £8,000. He still had to get the engine erected and to do so he entered into an agreement with Biddulph on 22 November 1833. This ended in litigation when the work was not completed on time.

Girard sued for £2,000 damages in May 1834 and the case resulted in argument about the amount that could be ground in a week with a 14 horsepower engine (a maximum of £35 in profit). The original damages awarded of £250 were reduced to £83 [24]. Later that year he was able to start up, claiming the ability to grind over 3,000 bushels a week and advertising a charge of one shilling per bushel, to be paid in cash or wheat, on consignments of 10 bushels and over. By 1837 he had extended his wharf into a timber wharf and was presumably using the steam engine to process the timber he was advertising when there was not enough grain for the flour mill. In 1838 or 1839 he sold up. The wharf brought him £27,000, was adapted for steamers by the Australian Steam Navigation Company and was known as the Hunter River wharf. The mills passed to the newly formed Sydney Flour Company that was managed by Thomas Chapin Breillat and eventually wholly owned by him.

Hughes and Hosking opened the Albion mills at the bottom of Market Street in 1833, which burned down in 1841. In 1839 Maclehose claimed that there were eight flour mills on Sussex Street 'all actively at work' but in his lists of merchants he only identifies four —Barker and Hallen, Dodds and Davies, Francois Girard, Hughes and Hosking [25].

By 1835, as the economic boom continued and as Darling Harbour attracted other industries and shipping, flour mills began to be constructed further away and the market in flour became more complex. The boom years of the 1830s that saw several more mills built in Sydney gave way to the 1840s bust that saw Barker and Hallen among others fall into bankruptcy. In 1844 Thomas Barker had taken the mill back and Michael Berry was running it. The Chippendale mill on Old Botany road, the one remaining watermill in Sydney, was being run by Thomas Pattrick but by 1848 he was insolvent with debts of £2609 and assets of £80 [26]. Some of the windmills were still working: Baird and Luker (or Lucas) were running Gordon's mill and C R Broughton the Phoenix mill in Darlinghurst. However, MacDonald and Airth who had been running the Craigend mill that was by now being called Hill's mill were insolvent in 1843, further victims of the depression. The mill was taken over by J O Wascoe and Henry Moody but soon passed as 'Oak Mill' to James Fidden who was still operating it in the 1850s.

The management of most of the steam mills was in new hands. JH Grose was overseeing the Victoria Mills and Henry Smithers Hayes the Brisbane steam mills. Few if any new mills appear and there were perhaps ten or 11 mills in all. In 1847, as the depression receded, the number of mills appeared to remain constant.

The recovery in the 1850s, coming as it did with the 'gold rushes' that led to many men downing tools and making for the gold fields, caused shifts in the management of the flour mills. Fortunately these changes and the associated growth also brought with them an increase in the price of flour [27]. This encouraged some new mills to be built and some new names that were to dominate the next quarter century would appear.

[1] Keith Farrer, To feed a Nation A History of Australian Food Science and Technology, CSIRO, Collingwood, 2005, pp 18–19

[2] The Australian Wheat Industry, 1301.0 - Year Book Australia 2006, Australian Bureau of Statistics website www.abs.gov.au/AUSSTATS/abs@.nsf/Previousproducts/1301.0Feature%20Article212006?, viewed 23 June 2016

[3] Cogs had teeth that were inserted around the wheel and had regularly to be replaced as they wore out. They needed to be made of a greasy wood type. In Britain apple wood was normally used but the millers in this unknown continent may not have found a suitable substitute. David Collins, Account of the English Colony in New South Wales ed Brian Fletcher vol. 1, Reed, Terry Hills, 1975, p 274

[4] James Wilkinson proposed a 'walking mill' that required two men, and while the wheel performed one revolution the mill-stones performed twenty such mills were commonly used in Europe to operate cranes or raise water from wells and could be donkey powered.

[5] David Collins, Account of the English Colony in New South Wales, ed Brian Fletcher vol. 1, Reed , Terry Hills, 1975, p 266

[6] Oliver Evans, Young Millwright and Millwrights Guide Evans, Philadelphia,1795 was available in Australia

[7] Correspondence Governor Hunter to the Duke of Portland, 12 November 1796 Historical Records of Australia, Series 1, vol. 1, Library Committee of the Commonwealth of Australia, Sydney, 1914, p 675.

[8] The Sydney Gazette and New South Wales Advertiser, 23 June 1805, p 2

[9] In 1772 a Scottish engineer Andrew Meikle invented a spring sail in which the sailcloth was replaced by hinged shutters along each sail at right angles to the whip; interconnected by bar spring tension they would spill the wind if it strengthened unexpectedly

[10] A post mill had wooden body on two or three floors that centred on a wooden post held by a trestle on the ground. A slightly more elaborated form sat on a round or octagonal base. They came in various shapes. Some had a flat front others had a cut away front so the windshaft could be canted 5-15% from the horizontal. They could not compete with smock and tower mill in terms of meal production.

[11] The New South Wales Calendar and General Post Office Directory 1832 , Stephens and Stokes, Sydney, 1832, p 83

[12] By 1900 all that was left were the stones, now in the Museum of Applied Arts and Sciences. Its precise location is disputed as is the location of its mill pond although it was clearly near Barcom Street or Glenview St Paddington.

[13] For a European example of this see J. L van Zanden The Strictures of Inheritance: the Dutch Economy in the Nineteenth Century, Princeton University Press, Princeton, 2004, p158.

[14] James Maclehose, Picture of Sydney and Strangers Guide in NSW for 1839, J Maclehose, Sydney, 1839, p 53

[15] James Maclehose, Picture of Sydney and Strangers Guide in NSW for 1839, J Maclehose, Sydney, 1839, pp182-3 where the imports for 1837 include 56,082 bushels of barley and 263,956 bushels of wheat valued at £94,413

[16] ME Robinson, The New South Wales Wheat Frontier 1851- 1911, ANU Research School of Pacific Studies Department of Human Geography Publication HG/10, Canberra, 1976, p 167

[17] Edgar Dunsdorfs, The Australian Wheat growing industry, Melbourne University Press, Melbourne, 1956 p 89. On p147 he lists all the wheats sown in SA in 1868

[18] WC Wentworth, A statistical historical and political description of the colony of New South Wales and its dependent settlements in Van Diemens Land, G. and W. B. Whittaker, London, 1819, pp 91-2

[19] Gwyneth M. Dow, Samuel Terry: the Botany Bay Rothschild, Sydney University Press, Sydney, 1974, pp 115-8

[20] The Sydney gazette, and New South Wales advertiser , 8 April 1824, p 3

[21] James Waldersee, 'Emancipist in a hurry: Francois Girard', Journal of the Royal Australian Historical Society, v 54, Sept 1968,p 238

[22] James Maclehose, Picture of Sydney and Strangers Guide in NSW for 1839, J Maclehose, Sydney, 1839, as with all such claims it is hard to count them on the ground and five or six seems the maximum.

[23] William Howitt, Land, labour, and gold, or, Two years in Victoria : with visits to Sydney and Van Diemen's Land, Longman, Brown, Green and Longmans, London, 1855, p 327

[24] Girard v Biddulph, NSW Supreme Court, 1834, NSW SupC 127, Decisions of the Superior Courts of New South Wales, 1788-1899 website, Macquarie University http://www.law.mq.edu.au/research/colonial_case_law/nsw/cases/case_index/1834/girard_v_biddulph/ viewed 10 October 2017

[25] James Maclehose, Picture of Sydney and Strangers Guide in NSW for 1839, J Maclehose, Sydney, 1839, pp 61,186-7

[26] Maitland Mercury 8 March 1848, p 2

[27] Dunmore Lang, The Australian emigrant's manual; or, A guide to the gold colonies of New South Wales and Port Phillip, Partridge and Oakey, London, 1852, p 91 has Barkers and the Victoria Mill on 14th May June flour per ton £18 fine and £16 seconds substantial higher than the 1840 figures